Choosing Between Oil-Lubricated and Oil-Free Rotary Screw Air Compressors

When selecting a rotary screw air compressor, the choice between oil-lubricated and oil-free models hinges on various factors. Ultimately, your choice depends on your specific needs, budget, and the level of air quality required for your application. Consider the following points to make an informed decision:

Oil-Lubricated Rotary Screw Compressors:

- Cost-Effective: Typically more budget-friendly upfront.

- Efficiency: Higher energy efficiency, translating to lower operating costs.

- Maintenance: Regular oil changes required, along with maintenance of oil filters.

- Air Quality: May have some oil carryover, suitable for industrial applications where perfect air purity isn't essential.

- Application: Ideal for applications where a small amount of oil carryover is acceptable, such as manufacturing and workshops.

Oil-Free Rotary Screw Compressors:

- Air Purity: Essential for industries demanding completely oil-free air, like medical, pharmaceuticals, and electronics.

- Low Maintenance: Less maintenance due to no oil changes or oil-related issues.

- Initial Cost: Higher upfront cost but potential long-term savings in maintenance and air quality.

- Efficiency: Slightly less energy efficient than oil-lubricated models.

- Noise Level: Generally quieter due to the absence of lubricating oil.

- Application: Crucial for industries where air quality is paramount, such as cleanrooms and sensitive manufacturing processes.

If you have any questions about choosing the right air compressor for your business, Contact Evergreen Compressed Air and Vacuum to talk to one of our experienced sales representatives!

INDUSTRIAL APPLICATIONS

Rotary screw air compressors serve as the backbone for many industries, ensuring consistent and reliable compressed air supply, driving critical processes, enhancing efficiency, and maintaining product quality.

MANUFACTURINGTEXTILESAUTOMOTIVEPHARMACEUTICALFOOD & BEVERAGEPAPER

MANUFACTURING

MANUFACTURING How do Air Compressors Serve the Manufacturing Industry?

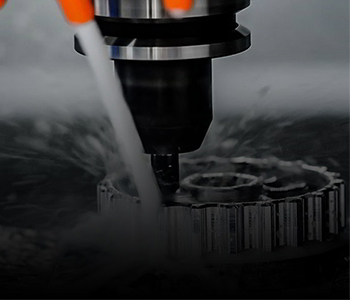

- Pneumatic Tools: Powering a wide range of pneumatic tools used in assembly lines and production processes.

- Efficiency: Delivering consistent and reliable compressed air for various applications, enhancing manufacturing efficiency.

- Automation: Enabling automation by providing the required energy for robotic arms and other automated machinery.

- Controlled Processes: Supporting precision control in manufacturing processes like welding, cutting, and shaping.

TEXTILES

TEXTILES How do Air Compressors Serve the Textile Industry?

- Pneumatic Machinery: Powering pneumatic devices used in spinning, weaving, and fabric finishing processes.

- Energy Efficiency: Efficiently driving air-jet looms and other textile machinery, reducing energy consumption.

- Consistent Airflow: Providing uniform compressed air essential for maintaining consistent quality in textile production.

AUTOMOTIVE

AUTOMOTIVE How do Air Compressors Serve the Automotive Industry?

- Pneumatic Tools: Driving air-powered tools for assembly, painting, and maintenance operations.

- Painting and Finishing: Supplying compressed air for painting booths and pneumatic paint guns.

- Precision: Enabling precision in automotive manufacturing processes, ensuring consistent quality.

PHARMACEUTICAL

PHARMACEUTICAL How do Air Compressors Serve the Pharmaceutical Industry?

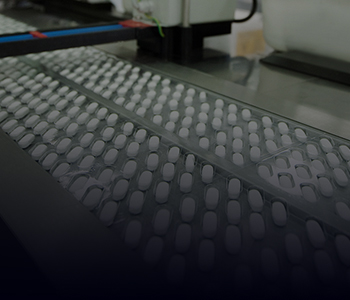

- Clean Air: Delivering oil-free and contaminant-free compressed air critical for pharmaceutical manufacturing.

- Hygienic Standards: Meeting stringent hygiene standards required for pharmaceutical production.

- Lab Equipment: Powering laboratory equipment and controlled environments without risk of contamination.

FOOD & BEVERAGE

FOOD & BEVERAGE How do Air Compressors Serve the Food & Beverage Industry?

- Food Safety: Providing clean, oil-free air necessary to maintain food safety standards.

- Packaging and Filling: Powering pneumatic machinery used in packaging, filling, and sealing processes.

- Conveyor Systems: Operating air-powered conveyor systems for efficient material handling.

PAPER INDUSTRY

PAPER INDUSTRY How do Air Compressors Serve the Paper Industry?

- Drying Processes: Supplying compressed air for drying paper during production, enhancing process efficiency.

- Paper Converting: Powering machinery used in cutting, folding, and processing paper products.

- Automation: Supporting automation in paper manufacturing, contributing to streamlined production.

WHY CHOOSE US

Financing Available

Energy Efficient Systems

Environmentally Friendly

Manufacturer Warranty

FREQUENTLY ASKED QUESTIONS

Choosing between oil-lubricated and oil-free compressors depends on your industry needs. Oil-lubricated models are cost-effective and energy-efficient, ideal for manufacturing, automotive, and general workshops. Oil-free models are recommended for industries like pharmaceuticals, food & beverage, and electronics, where pure air is critical.

Oil-lubricated compressors require periodic oil changes, filter replacements, and regular system checks. Oil-free models have lower maintenance needs but should still be serviced regularly to maintain efficiency and longevity. Evergreen offers tailored maintenance programs to keep your system running smoothly.

We provide a wide range of ELGi rotary screw compressors, from 4 HP to 300 HP across both EN and EG Series, with options for base mount, tank mount, VFD, and integrated dryer systems — making it easy to match your exact application and space requirements.

Yes! Evergreen Compressed Air and Vacuum provides end-to-end support — from product selection and installation to routine maintenance and emergency service — across Seattle, Olympia, Everett, and surrounding cities in Washington State.

Simply fill out the contact form on this page with your details. One of our sales representatives will reach out to discuss your requirements and recommend the most efficient compressed air solution for your business.