Evergreen Compressed Air and Vacuum partners with some of the most trusted compressed air equipment manufacturers, guaranteeing best-in-class energy efficiency and long-lasting durability. This ensures that your compressed air system delivers the most cost-effective ownership experience.

Evergreen provides ELGi rotary screw air compressors, which excel in energy efficiency and dependability, setting the benchmark in the industry. These air compressors are supported by an Uptime Guarantee so that you can have confidence that your compressed air system will run seamlessly throughout production. ELGi rotary screw air compressors offer both oil lubricated and oil-free air compressor models, accompanied by integrated VFD controls. This combination optimizes efficiency while meeting the required air quality standards.

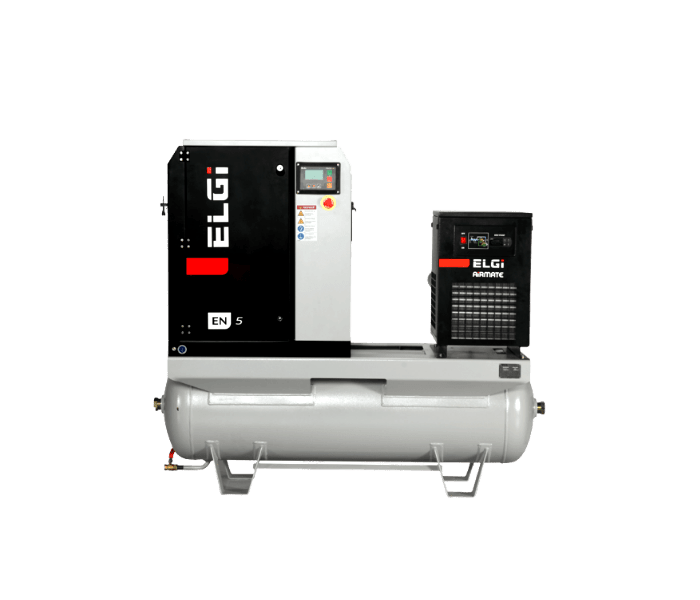

EN Series Rotary Screw Air Compressors 4–20 Hp

ELGi EN Series compressors provide enhanced value and increased operational efficiency for your investment. ELGi EN Series Compressors deliver elevated uptime.

View ProductsEQ SERIES SCREW AIR COMPRESSORS 25 – 30 HP

The ELGi EQ Series offers unmatched reliability, built tough for a long-lasting performance. Backed by a best-in-class warranty and requiring minimal maintenance, it stands out as a reliable air compressor for industries where size,

View ProductsEG Series Rotary Screw Air Compressors 15–300 Hp

The ELGi Global (EG) Series compressors embody direct drive operation, best-in-class UPTIME, energy efficiency, and versatile optional features, representing a substantial advancement in design.

View ProductsWhat is a Rotary Screw Air Compressor?

Rotary screw compressors are categorized as positive displacement compressors, functioning by capturing air between interlocking helical screws or rotors in motion. Its primary purpose is to deliver an uninterrupted stream of compressed air, serving diverse industrial needs. These versatile air compressors excel in consistent and efficient operation, making them well-suited for diverse industrial environments necessitating a steady provision of compressed air. Available in a variety of sizes and capacities, they cater to distinct air demand prerequisites.

Evergreen offers both oil-lubricated and oil-free compressors.

WHAT ARE THE BENEFITS OF ROTARY SCREW AIR COMPRESSORS?

- High Efficiency : Screw-type compressors are generally more efficient. They produce less energy waste, which means they can deliver more compressed air output for the energy input they consume.

- Continuous Operation : Rotary screw air compressors can operate continuously without the need for frequent starts and stops. This makes them ideal for applications that require a consistent and reliable supply of compressed air.

- Reliability : With less moving parts and a balanced design, they are known for their reliability and durability, requiring less maintenance and reducing downtime.

- Low Noise : Due to advanced noise reduction technology, these air compressors operate at lower noise levels, which can be advantageous for indoor applications or noise-sensitive environments.

- Compact Design : Rotary screw compressors have a space-efficient design, which makes them suitable for installations where space is limited.

Maximize Efficiency with Integrated VFD Controls

ELGi rotary screw type air compressors are equipped with Variable Frequency Drive (VFD) controls that help maximize energy savings by adjusting the compressor speed to match air demand. This feature not only reduces power consumption but also improves operational efficiency.

- Energy Savings : VFDs allow the compressor to adapt to real-time demand, reducing energy waste and saving on operational costs.

- Extended Compressor Life : With smoother, more efficient operation, VFDs also help reduce wear and tear, extending the lifespan of the equipment.

What are the common industries for rotary screw air compressors?

From assembly lines to painting and sanding operations, they play a crucial role in automotive manufacturing processes.

These compressors are extensively used in manufacturing processes for powering pneumatic tools, controlling machinery, and maintaining consistent air pressure for production lines.

The textile industry relies on compressed air for various processes such as spinning, weaving, and dyeing fabrics. /p>

From assembly lines to painting and sanding operations, rotary screw compressors play a crucial role in automotive manufacturing processes.Screw compressors can provide contaminant-free and oil-free air required for critical pharmaceutical processes and packaging.

Compressed air is used for packaging, conveying materials, operating pneumatic systems, and ensuring cleanliness in food and beverage processing facilities.

Paper

Compressed air powers presses, cutters, and other equipment in printing and paper production.

From automotive to pharmaceuticals, ensure your system runs smoothly with high-quality air compressor replacement parts.